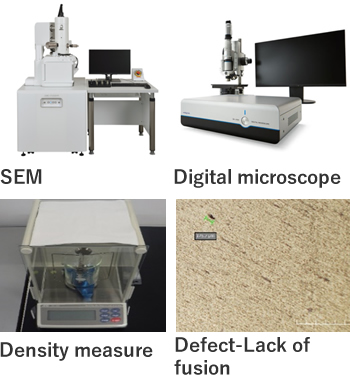

JAMPT are striving for optimizing the process parameters in order to obtain the quality required by our customers, when dealing with customers’ original material, or when working on unique geometry such as cavity, inner-channel and thin-wall with new material. By going through the necessary verification process, we optimize the parameters optimum time and cost. JAMPT has dealt with a wide variety of materials and shapes for 10 years and has cultivated experience and know-how . In addition, JAMPT has a wide lineup of printers that can meet various demands. Moreover, JAMPT has the Equipment List needed to evaluate and consider optimal parameters through minimal trials and errors. By using a SEM, Digital microscope, X-ray CT, 3D scanner, we evaluate test-pieces. Then, we measure mechanical properties of the test-piece printed with the optimized parameters. We are well-equipped, capable of conducting in-house tests from analysis and evaluation of material powder to test printing and analysis and evaluation of printed objects, and we can respond to flexible development process in a short period of time with our experience and knowledge. We support a wide range of activities in AM, from basic AM material evaluation to AM parts development, so please feel free to contact us.

Duration:2weeks