We use metal powder equivalent to tough pitch copper and manufacture products by using metal 3D printers (AM).

Unlike conventional cutting and pressing, the shape of the product is formed directly from the metal powder without mold.

We can 3D print pure copper in a short period of time, which is currently extremely difficult for mainstream laser beam AM technology.

| AM technology | Size | Speed | Complicated Shape | Cost |

|---|---|---|---|---|

| JAMPT’s Electron Beam Type AM Technology | 〇 | 〇 | 〇 (Removal of sintered powder )※1 |

〇 |

| Green Laser Type AM Technology | △ | △ | 〇 | △ |

| Conventional Laser Type AM Technology | × Currently Impossible※2 |

|||

| Blue Laser Type AM Technology (under development) | ? | △? | 〇 | △? Highly cost machines? |

※1 Complex hollow structures can be difficult because the sintered body must be removed after molding.

※2 Although manufacturing may be possible using an expensive high-power laser, but cost could be a problem.

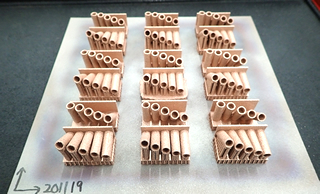

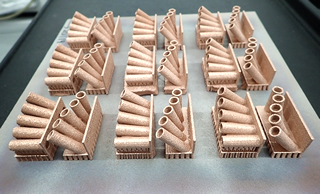

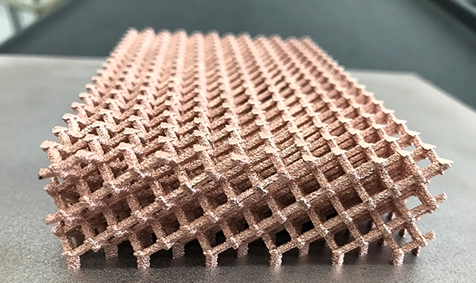

By working on optimizing the modeling conditions to be set and input to the 3D printer device, we could establish stable manufacturing quality matching the customer's design shape.

In addition, we will assist you in optimizing and redesigning the shape unique to AM.

Lattice wire diameter @ 1mm

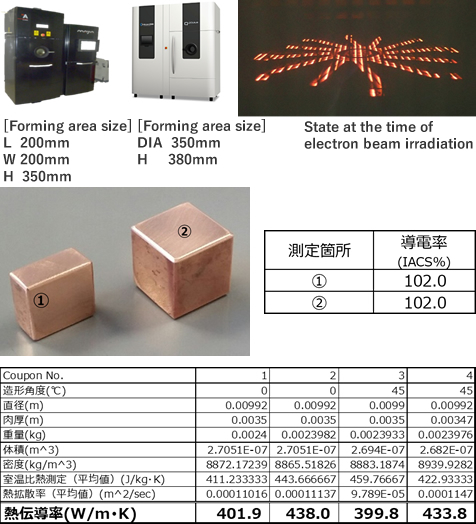

With 3D printer (AM) manufacturing, we have confirmed the same physical properties (conductivity / thermal conductivity) as conventional materials.

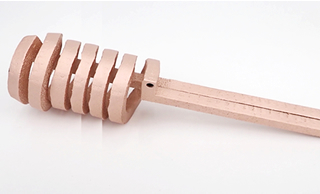

We have received requests for trial production and development of heat dissipation materials and coils from various industries.

【EBM machines used】

With the rapid development of electrification technology to reduce CO2 emissions, attention is focused on efforts to utilize pure copper with high conductivity, including motors, in AM technology. Major overseas AM equipment manufacturers are conducting research and development to enable modeling of pure copper materials that could not be modeled with general-purpose equipment by using green, blue, or high-intensity lasers. A copper alloy material that can be used for conventional fiber laser installed AM equipment is being developed.

Normally, pure copper power materials equivalent to oxygen-free copper / tough pitch copper with a copper content of 99.9% or more cannot be stably melted (cannot melt the powder bed) by the laser melting method due to its high reflectance and thermal conductivity and not able to conduct AM production. JAMPT can solve this technical problem by using an AM machine that uses electron beam as a heat source (JAMPT is one of the few companies who owns such machines in Japan), and realizes stable AM production by optimizing the heat input and melting conditions during manufacturing.

Pure copper has been widely used in coils and heat exchangers due to its high conductivity and thermal conductivity, but since it is a highly expandable and diffusible material, it is difficult to perform precise processing, and due to heat diffusion, welding is also difficult. When molding into a complicated shape is required, processing such as brazing has been performed.

In AM production with pure copper, which is a material with a low melting point, it is very difficult to determine the optimum heat input conditions and melting conditions. Thermal stress can be removed in the process of preheating, which is a feature of electron beam laminating equipment. Nevertheless, it was found that the material is prone to thermal deformation in the AM process, which undergoes rapid melting and solidification. In addition, as described above, in the preheating process performed by the electron beam method, the powder around the manufactured object forms a preliminarily sintered body, so post-processing for removing the preliminarily sintered body is required after the manufacturing is completed, which is complicated. It was found that there is a technical problem in removing the preliminarily sintered body inside when manufacturing a hollow structure or an internal flow path.

We have received requests for AM production using pure copper with our electron beam machines for areas such as, basic research for prototype automobile (EV/FCV) parts, ), prototypes and practical products of coils used in induction hardening processes, and prototypes for use in heat sinks that require high heat dissipation performance, etc. We would like to continue to support the creation of unprecedented products by AM production with pure copper, so please feel free to contact us.